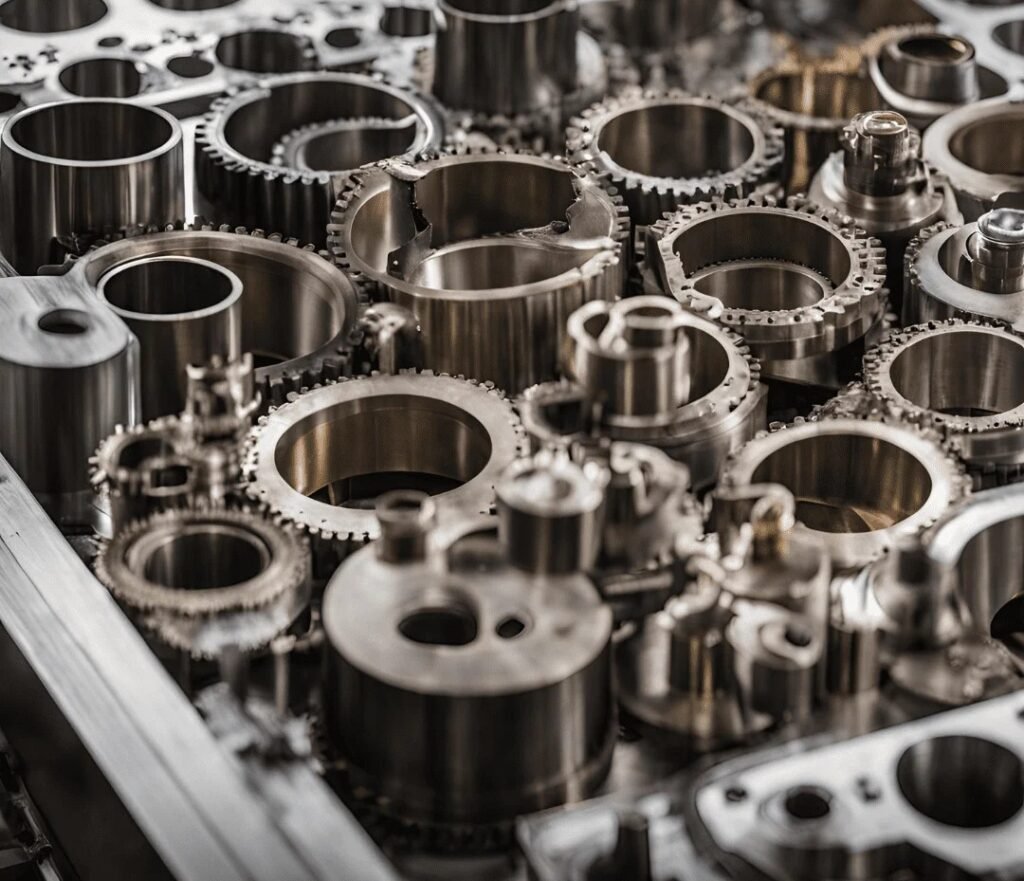

In industries where metal components are subjected to repeated stress, ensuring longevity and durability is crucial. Shot peening and stress peening are advanced surface enhancement techniques that improve the fatigue resistance of components, reducing the risk of failures. At Metablast, we provide cutting-edge peening solutions tailored to your industry needs, ensuring optimal component performance and reliability.